Home news

RECOMEN MARINE ROPE USING

Release time:2020-07-15

How to right use a marine rope, the following you can find the answer:

1. Meeting the minimum breaking load (MBL)

MBL is a key performance of a vessel. The MBL of RECOMEN ROPE must match the design standard of the vessel.

2. Using the rope at good environment:

The melting point of RECOMEN ROPE is low, so the mooring rope can’t be used in the environment where the temperature is above 70℃.

3. Depending on the Load needing to choice the right rope diameter.

4. The recommended length of the mooring rope is 220, 300m,or depend on customer requirement.

5. Spliced right length eyes.

Spliced eyes at both ends (soft eyes), the usual length of the spliced eyes is 1.8m to 2.5m

6. Avoiding using full load

RECOMEN ROPE can’t be used too close to its full capacity, because the large amount of accumulated energy will cause rope degradation. Special attention must be paid to creep phenomena such as that ropes become hard, and strands are difficult to be separated.

7. Avoiding the rope temperature rise very fast

To avoid rapid temperature rise in some parts of the rope, do not allow RECOMEN rope to be chaffed with steel wire rope.

8. The use attention on winches

a. Additional care: Cover the metal surfaces (of the chocks especially) with PES (or even better with UHMWPE material) chafe clothing for better protection against abrasion

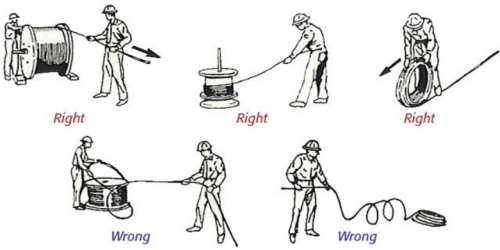

b. Uncoiling from a coil: The coil must be free to rotate (vertically or horizontally) and unwind the rope. Wind carefully the rope on the storage drum using an appropriate device. Apply a small reference tension but mind the tension as well as the speed level to avoid the generation of excessive heat due to friction/abrasion. The first wraps must be as tight and firm as possible to avoid the slipping down of the wraps from the top of the coil.

c. Uncoiling from a reel: The reel must be free to rotate (vertically or horizontally) and unwind the rope from the top of the reel. The first layer must be wound on as close as possible. The next layers should be stacked on the valleys of the previous layer (as shown in the picture) or in a crossed over

manner. NEVER stack a layer exactly above the previous one.

d. Very bad drum condition (signs of rust, sharp surfaces) which leads to extreme

rope abrasion. Rough surfaces will damage the rope’s jacket.

The surface of winch should be clean and smooth, if not it should be polished and painted.

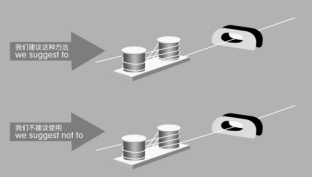

9. Using on double-bits

RECOMEN ROPE is used on the double-bits, secure the mooring ropes in a figure-8 pattern, in the way like the below picture.

10.Keep good Storage.

RECOMEN ROPE shall be kept away from the source. The storage or working place ambient temperature should not be higher than 70?C.

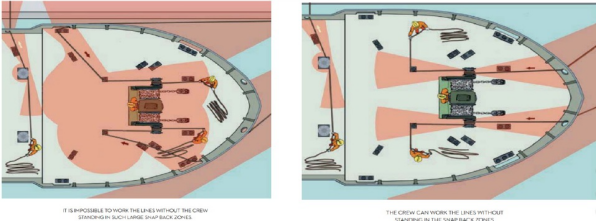

11. STAY AWAY from the snap back area, as seen in the drawing below, when the line is under tension. Ropes have a very reduced snap back reaction, limited and almost negligible, however, it is good for the personnel to get acquainted with the behaviour of the synthetic ropes.(that also have no snap back reaction).

![]()

12. Avoiding twist the rope severe times.

Severe twist of ropes is not allowed. Twists of four turns per three feet (or meter) introduced into the line can cause as much as 10 to 30% reduction of strength.

Twisted severe times will reduce the strength to 30%

13. Avoid making knots at all costs. They can reduce the line's strength by up to 50%. Make eye splices instead.

14. Avoid shock loads (always use a mooring tail). Use chafe gear (we strongly recommend UHMWPE webbing sleeves) for the contact of the rope with metal surfaces (bits, bollards, chocks etc) no matter in how good condition these hardware are.

15. Every six months reverse your mooring line (bring the rear part of the rope in front and vice versa ) so that the wear is distributed and get a longer service life.

Add: No.136 Longmenshan Road, Huangdao District, Qingdao

Tel: 0532-86993625

WhatsApp/Mob:+86 13373696110

E-mail:ida@recomenmarine.com

Yangzhou Recomen Rope Co., Ltd.